A unique foam

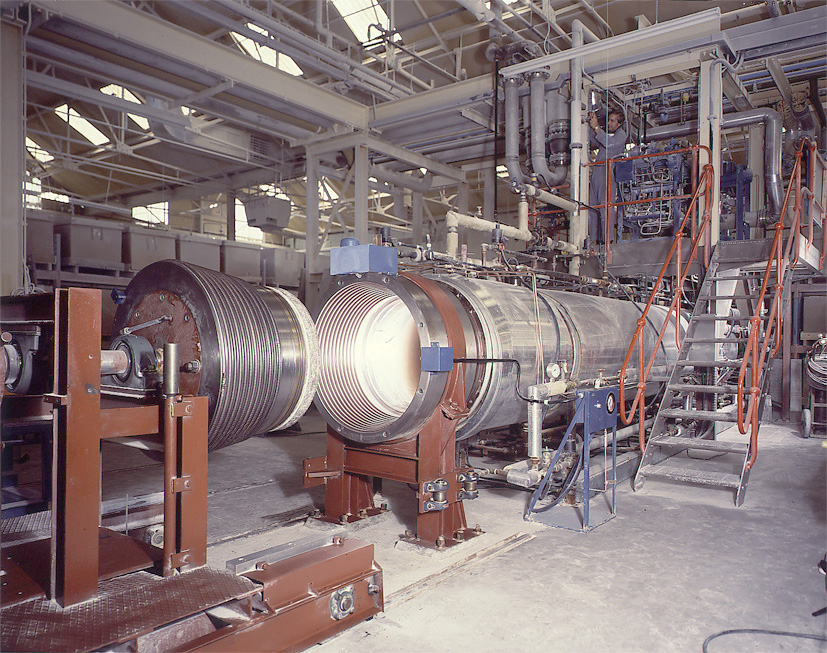

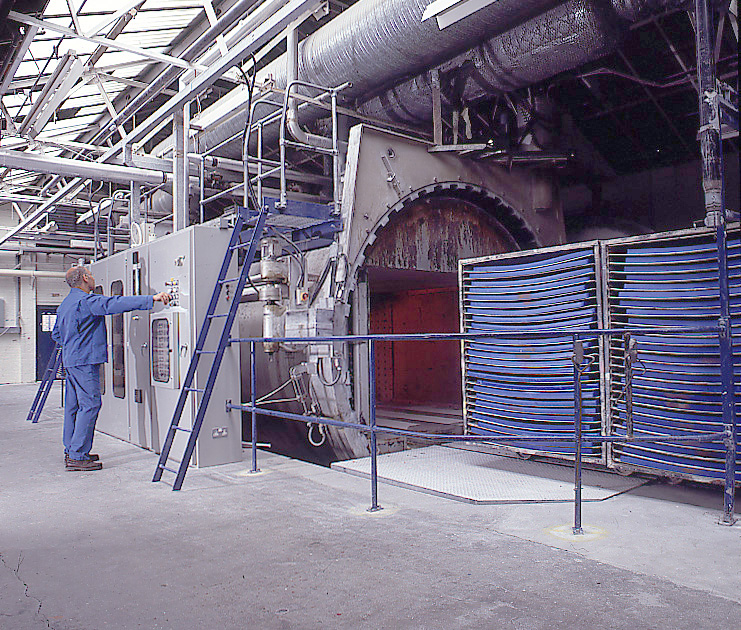

Zotefoams products are manufactured using a truly unique process technology. This involves dissolving nitrogen gas into a plastic sheet at extreme pressures and temperatures. On releasing this pressure and temperature the gas increases its volume to such an extent that it expands the plastic into a foam.